How Do 3D Printers Work?

3D printers are poised to make a splash in 2015. Tech Talker explains what they are, how they work, and why they’re likely to be such a game-changing technology.

Listen

How Do 3D Printers Work?

In the episode What to Expect in Tech in 2015, I mentioned 3D printers as one of the technologies that would boom in 2015. I want to do 3D printers justice, so in this episode, I’ll cover what they are, how they work, and why they’re poised to be such a game-changing device in the near future..

What Are 3D Printers?

To print something in 3D, you can design what you want to print on your computer ahead of time, or load a design that someone else has already made. Getting started with designing objects in 3D is easier than it sounds. If you head over to 3DTin.com, for example, you can start designing 3D objects for free—no software install required. Everything is done in your Internet browser. A couple other 3D modeling software sites you should check out include AutoDesk 123D and Sketchup.

How 3D Printers Work

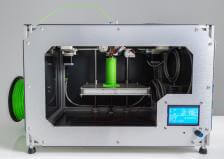

3D printers vary in shape and size, and by materials used. Generally, most 3D printers available to consumers use an ABS filament, which is basically a tough plastic wrapped around a spool. ABS filaments come in all different colors, so your designs can get very creative. The printer uses this ABS filament as the “ink” to print your designs. The printer starts building your design from the ground up, slowly layering the melted filament on top of itself. Fully printing a product can take hours based on the complexity of the design.

The size of your 3D printer is pretty easy to determine based upon what it is you want to print. For example, most 3D printers on the market can print a solid object that’s about 6″ by 6″ on the base and close to a foot high. The larger the design you want to print, the more time you’ll have to wait and the more expensive the 3D printer you’ll need to buy.

Right now, a decent home 3D printer will cost around $1,000. Specifically, I’m referencing the Cube3 created by 3DSystems. This is probably one of the best 3D printers for beginners and will allow you to hit the ground running. There’s also Makerbot’s Replicator Mini and the Dremel Idea Builder. All three of these printers fall in that $1000 price range and vary in features such as printing size and allowed materials.

If you’re not really interested in buying a 3D printer but want to see what the fuss is about, I highly recommend checking out Ponoko.com. You can upload your 3D design to this website and they will print the item for you and ship it to you right away. It’s pretty slick and allows you to get a handle on 3D printing with minimal investment other than your time to design your project and the price of having your design printed.

Why 3D Printers Are a Game Changer

In one case, when astronauts needed a ratcheting wrench, NASA simply emailed them the design file of the wrench needed, and then the astronauts printed the wrench aboard the space station. Obviously, not all of us need a wrench in space, but the ability to print physical objects on demand, at home will revolutionize manufacturing and prototyping. For example, say a small piece of your car breaks. Right now, you’d probably need to take it to a mechanic who would look up the model of your car and then order the part. With a 3D printer, you could go to your car manufacturer’s website and print that piece from the design file you downloaded from them, saving you a ton of time and hassle.

It’s the power of world wide collaboration brought to the physical world.

As more people get involved in 3D printing, more designs will get released on the Internet, and it will be so much easier to Google whatever object you’re looking for. Soon, everything from tools, to toys, to parts and even full-on copies of normal household objects will be available online.

What I love most about 3D printing, though, is that designs can be treated like open source code. They can be distributed freely, and you can make your own changes to them, as well as share your own new designs. Instead of having a few designers working on one product, you can have thousands of people working on a single design.

It’s the power of world wide collaboration brought to the physical world, and that, for me, is a huge game changer.

Well, that’s it for today! Be sure to check out all my earlier episodes at techtalker.quickanddirtytips.com. And if you have further questions about this podcast or want to make a suggestion for a future episode, post them on Facebook QDTtechtalker.

Until next time, I’m the Tech Talker, keeping technology simple!

Female architect using a 3d printer, 3d printer with bright green filament, filament for 3d printer images courtesy of Shutterstock